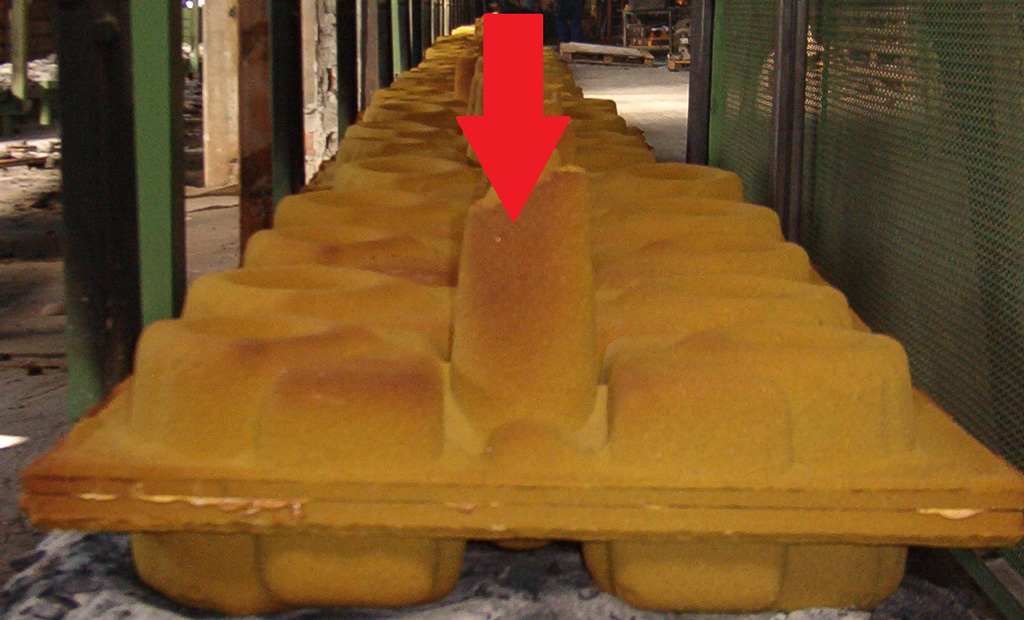

Shell moulding is a technology used to produce castings on the net near shape concept.

The particular system of production of a thin rigid shell is able to obtain geometry on casting with restricted tolerance, finished and smoothness surface and complex shape

Much more than a system to shape the geometry

This system is providing a number of other advantages. Further the first possibility to use the geometrical quality of a shell moulded part, the other points focus on the thermic and mechanical characteristics of the shell mould. These characteristics are the bases for a reliable and advanced casting part.

Material produced

- Gray Iron

- Compacted Graphite Iron

- Ductile Iron

- Alloyed Cast Iron

- Carbon Steel

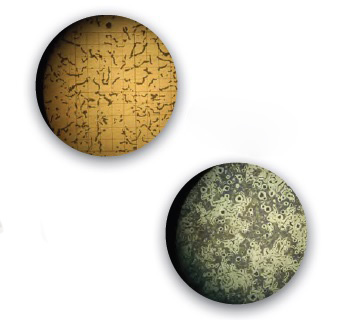

Compacted Graphite Iron

Compacted Graphite Iron (CGI) is the better compromise that the metallurgy of iron is able today to offer for mechanical solution.

Elevated mechanical performance in reference to gray iron;

Elevated mechanical performance in reference to gray iron;- Elevated machinability in reference to ductile iron;

- Better castability in reference to gray and ductile iron;

CGI Mechanical Characteristics – ISO 16112

| Material designation | Tensile strengthRm

N/mm2 min. |

0,2%proof strengthRp 0,2 N/mm2 min. |

Elongation

A % min. |

Typical Brinell hardness range HBW 10/30 |

|---|---|---|---|---|

| ISO 16112/JV/300/S | 300 | 210 | 2,0 | 140 to 210 |

| ISO 16112/JV/350/S | 350 | 245 | 1,5 | 160 to 220 |

| ISO 16112/JV/400/S | 400 | 280 | 1,0 | 180 to 240 |

| ISO 16112/JV/450/S | 450 | 315 | 1,0 | 200 to 250 |

| ISO 16112/JV/500/S | 500 | 350 | 0,5 | 220 to 260 |